The demand for brick making machines has been on the rise in recent years due to several factors, including:

Increasing construction activities: The demand for bricks has increased due to the growth of construction activities in both urban and rural areas. Brick making machines offer a cost-effective and efficient way to produce bricks in large quantities to meet this demand.

Sustainable building materials: Bricks are a sustainable building material that can be recycled and reused, making them a popular choice for environmentally conscious builders. Brick making machines that use eco-friendly materials such as clay, fly ash, and concrete are in high demand.

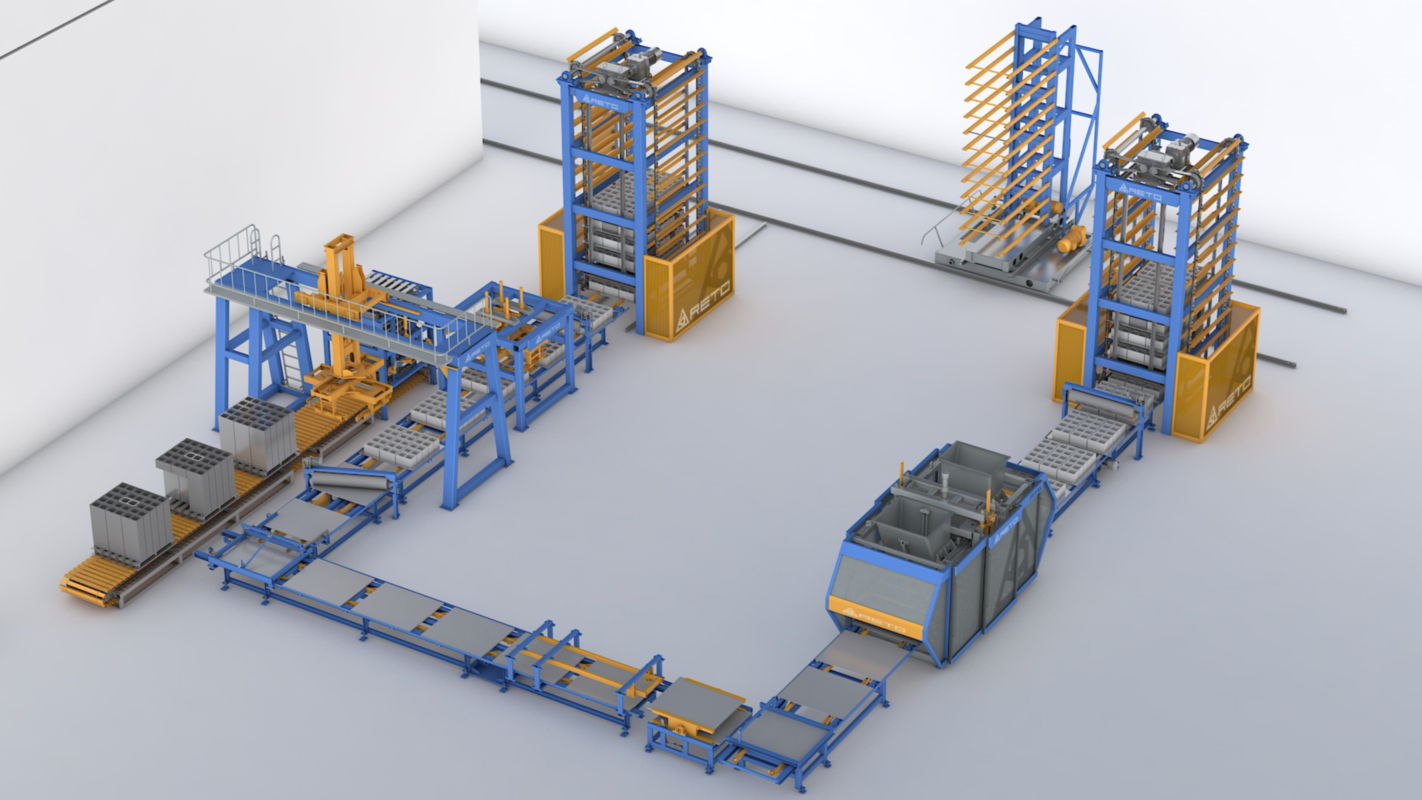

Automation and technology: Advancements in technology have led to the development of automated brick making machines that can produce high-quality bricks with minimal human intervention. These machines are fast, efficient, and require minimal maintenance, making them a popular choice for brick manufacturers.

Small business opportunities: Brick making machines are affordable and easy to operate, making them an attractive option for small business owners who want to start a brick manufacturing business. This has led to an increase in the number of small-scale brick manufacturers who are using brick making machines to produce bricks.

Overall, the growing demand for bricks, the popularity of sustainable building materials, and the advancements in technology have contributed to the increasing demand and usage of brick making machines.

What are some of the challenges faced by small-scale brick manufacturers who use brick making machines?

Small-scale brick manufacturers who use brick making machines face several challenges, including:

Access to capital: Starting a brick manufacturing business requires a significant amount of capital, concrete block machines and many small-scale manufacturers struggle to secure funding to purchase the necessary equipment and raw materials.

Lack of technical expertise: Operating a brick making machine requires technical expertise, and many small-scale manufacturers lack the necessary skills and knowledge to operate the machines effectively.

Limited market access: Small-scale brick manufacturers often struggle to access markets for their products, as they lack the resources and infrastructure to transport their bricks to potential buyers.

Competition from larger manufacturers: Small-scale brick manufacturers face stiff competition from larger manufacturers who have the resources and capacity to produce bricks in large quantities, often at a lower cost.

Unpredictable market demand: Market demand for bricks can be unpredictable, and small-scale manufacturers may struggle to meet fluctuating demand levels, resulting in production inefficiencies and wasted resources.

Environmental concerns: Brick manufacturing can have a significant environmental impact, particularly in terms of greenhouse gas emissions and land use. Small-scale manufacturers may struggle to implement environmentally sustainable practices due to limited resources and technical expertise.

Overall, small-scale brick manufacturers who use brick making machines face several challenges related to funding, technical expertise, market access, competition, production efficiencies, and environmental sustainability.