Introduction

In the pursuit of energy efficiency and sustainability, EC centrifugal fans have emerged as innovative solutions for air movement in various applications. These fans, equipped with electronically commutated (EC) motors, offer exceptional efficiency, precise control, and reduced environmental impact. In this article, we will explore the features, advantages, and applications of EC centrifugal fans, highlighting their role in revolutionizing the way we achieve efficient and sustainable ventilation.

Understanding EC Centrifugal Fans

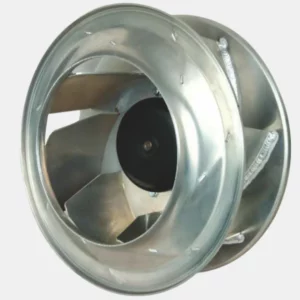

EC centrifugal fans combine the benefits of centrifugal fan design with electronically commutated motors. The EC motor technology utilizes permanent magnets and electronic control to achieve high efficiency and precise speed control. When paired with a centrifugal impeller, these fans deliver powerful, controlled airflow with superior energy efficiency.

Key Features and Benefits

- High Energy Efficiency:

EC centrifugal fans are renowned for their exceptional energy efficiency. The electronically commutated motors offer higher motor efficiency compared to traditional AC motors, resulting in reduced power consumption and lower operating costs. These fans can significantly contribute to energy savings and environmental sustainability. - Precise Speed Control:

One of the standout advantages of EC centrifugal fans is the ability to precisely control fan speed. The EC motor technology allows for continuous speed modulation, enabling users to adjust the airflow and pressure output according to specific requirements. This level of control enhances system performance, minimizes energy wastage, and optimizes ventilation effectiveness. - Quiet Operation:

EC centrifugal fans are designed for low-noise operation. The advanced motor technology, coupled with optimized fan blade design and housing construction, reduces noise levels significantly. This makes these fans suitable for noise-sensitive environments, such as residential spaces, offices, and hospitals, where quiet operation is essential. - Enhanced System Integration:

EC centrifugal fans are designed for seamless integration into various ventilation systems. They often come equipped with built-in control interfaces that enable easy integration with building automation systems or external speed control devices. This flexibility allows for centralized control and monitoring of multiple fans, enhancing overall system efficiency and performance. - Reduced Maintenance:

EC centrifugal fans require minimal maintenance compared to traditional fan systems. The absence of brushes in the EC motors eliminates the need for regular motor replacement or brush maintenance. This translates into reduced downtime, lower maintenance costs, and increased system reliability. - Environmental Sustainability:

The high energy efficiency of EC centrifugal fans directly contributes to environmental sustainability by reducing greenhouse gas emissions. These fans align with the global trend towards energy conservation and can help organizations meet their sustainability goals.

Applications of EC Centrifugal Fans

- HVAC Systems:

EC centrifugal fans find extensive use in heating, ventilation, and air conditioning (HVAC) systems. They deliver efficient and controlled airflow for space ventilation, air distribution, and temperature regulation in both residential and commercial buildings. - Data Centers:

Data centers require precise cooling and ventilation to maintain optimal operating conditions. EC centrifugal fans offer the necessary airflow and pressure to cool servers and equipment while ensuring energy efficiency and reliable performance. - Industrial Applications:

In industrial settings, EC centrifugal fans are employed for process cooling, exhaust ventilation, and air pollution control. Their energy efficiency and precise control capabilities make them suitable for applications requiring precise airflow and pressure regulation. - Cleanrooms and Laboratories:

EC centrifugal fans play a vital role in maintaining clean and controlled environments in cleanrooms and laboratories. They assist in air filtration, particle control, and maintaining stable air pressure differentials, contributing to the integrity of sensitive processes and experiments. - Commercial Kitchens:

Commercial kitchens require robust ventilation systems to remove heat, steam, and cooking odors. EC centrifugal fans efficiently extract and exhaust air, ensuring a comfortable and odor-free environment for kitchen staff and patrons.

Conclusion

EC centrifugal fans represent a significant advancement in efficient and sustainable air movement technology. With their high energy efficiency, precise speed control, quiet operation, and reduced maintenance requirements, these fans offer numerous benefits in a wide range of applications. Whether in HVAC systems, data centers, industrial facilities, or cleanrooms, EC centrifugal fans provide optimized airflow, reduced energy consumption,ec centrifugal fan and improved environmental sustainability. By embracing EC centrifugal fans, organizations can achieve superior ventilation performance while reducing their carbon footprint and promoting a greener future.