Digital peristaltic pumps stand as a testament to technological advancements in fluid handling, offering precision, control, and enhanced functionality in various industrial and laboratory applications. This article aims to explore the features, functionalities, and significance of digital peristaltic pumps in delivering accurate and versatile fluid transfer solutions.

Evolution to Digital Peristaltic Pumps

Integration of Digital Technology:

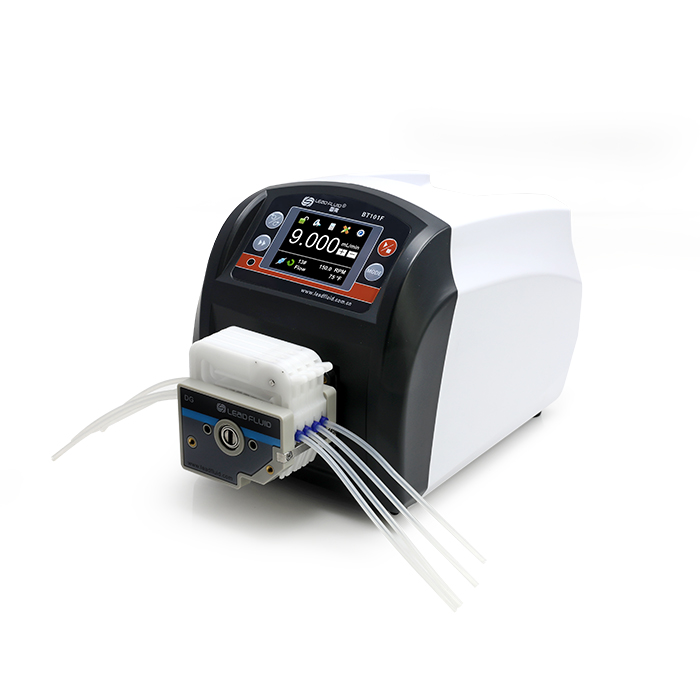

- Enhanced Control Systems: Digital peristaltic pumps utilize advanced electronic systems to regulate flow rates, offering precise and programmable control over dosing.

- Intuitive Interface: These pumps often feature user-friendly digital interfaces for setting parameters, monitoring operations, and adjusting settings as needed.

Features and Advantages

Precise Flow Control:

- Digital Precision: Digital control mechanisms allow for precise adjustment of flow rates, enabling accurate dosing and maintaining uniform fluid transfer.

- Programmable Settings: Users can set specific dosing schedules, intervals, or flow rates, enhancing automation and efficiency in fluid transfer processes.

Enhanced Functionality:

- Remote Operation: Some models feature remote control options, enabling monitoring and adjustment of pump settings from a distance, enhancing convenience.

- Data Logging and Connectivity: Digital pumps may offer data logging capabilities, allowing users to track dosing history and connectivity options for data transfer or integration with other systems.

Importance in Various Industries

Laboratory and Research Settings:

- Experimental Precision: Digital peristaltic pumps are vital in laboratories for precise and controlled fluid dosing in experiments, ensuring accurate results.

- Automation and Integration: Their programmable nature facilitates integration with analytical instruments, supporting automated workflows.

Industrial and Chemical Processing:

- Optimized Chemical Dosing: These pumps ensure accurate dosing of chemicals in industrial settings, promoting process efficiency and maintaining quality standards.

- Process Control: Digital peristaltic pumps contribute to accurate dispensing, ensuring consistent and controlled chemical handling in manufacturing processes.

Ensuring Operational Efficiency

Calibration and Maintenance:

- Regular Calibration: Periodic calibration ensures accuracy in dosing and maintains optimal pump performance.

- Routine Maintenance: Proper maintenance practices, including tubing inspection and replacement, are vital for sustained performance.

Digital peristaltic pumps represent a significant leap forward in fluid handling technology, offering precise dosing, enhanced control, and increased functionality across various industries. Their digital capabilities enable accurate and programmable dosing, fostering automation, and supporting precise fluid transfer in laboratories, industrial settings, and research environments. By embracing digital innovation, these pumps contribute to operational efficiency, process control, and adherence to stringent quality standards. Regular calibration, maintenance, and leveraging the technological advancements of digital peristaltic pumps ensure reliable and accurate fluid transfer solutions in diverse applications.